RMSensor works with a new and unique principle to achieve the highest possible sensitivity. This enables the measurement of extremely weak vibrations and very low frequencies. This means that events that were previously difficult to log/measure with, for example, a geophone, can now be detected/observed.

RMSensor One

A completely new type of patented Seismic Sensor

The Product and Its Features

RMSensor converts vibrations in the ground or air into electrical signals. The sensor is a completely new type of product on the market that essentially has the same applications and form factor as the historically most well-known type of seismic ground sensors, Geophones.

RMSensor stands out from Geophones as it operates on a new and unique principle to achieve the highest possible sensitivity, allowing the measurement of extremely weak vibrations with an extremely low noise level, even at very low frequencies.

The difference lies in a patented principle based on a freely suspended magnet instead of the traditional spring suspension used in Geophones, which imposes limitations on dynamics and sensitivity.

RMSensor vs Geophones

In Geophones, the magnet is fixed, and the coil is suspended in springs, making the construction highly dependent on the sensor’s inclination in relation to the plumb line, resulting in limited sensitivity with a few degrees of deviation.

In the newly developed RMSensor, the movable, completely freely suspended magnetic mass inside a cylinder is balanced by two opposing magnetic fields surrounded by coils. When the sensor is subjected to excitation/impact from a vibration generated by the environment, the magnetic mass will move against the coils and generate a voltage in them. With the freely suspended magnetic mass, friction and the impact of spring coefficients are minimized, resulting in significantly better signal-to-noise ratio and sensitivity.

In several practical experiments, it has been clear that RMSensor provides several dB higher signal response than Geophones under the same impact, as well as an extremely good signal-to-noise ratio S/N. RMSensor has a design that creates significantly greater tolerance for relatively large deviations from the plumb line.

Examples of Application Areas

Early detection of harmful vibrations/resonances in buildings and other types of structures

Prospecting in industries such as oil/gas or mining with greater precision

Monitoring of valuable machinery and warning of harmful low-frequency resonances in turbines, wind turbines, which could lead to serious breakdowns with high costs and prolonged downtime.

Detecting and alerting to intrusions in sensitive military/civilian facilities, e.g., nuclear power plants

Monitoring of border crossings between different countries (e.g., vehicles, people in motion)

Underwater application – detecting weak sounds/vibrations that occur during underwater activities (similar to hydrophones).

With customized software and suitable algorithms, the signal from RMSensor can be analyzed/calibrated, and profiles can be created to limit the algorithm analysis to specific frequencies/areas and a certain type of signal, e.g., footsteps, moving vehicles, and/or harmful resonances in bridges.

RMSensor can be used in many more applications than the examples listed above. With an external data logger, information can also be transferred to various cloud services, e.g., via the MQTT protocol.

Innovative Value

RMSensor has unique characteristics when it comes to detecting signals in various market sectors. Its features open up new opportunities to detect events that have previously been difficult to identify. This creates new possibilities for monitoring the environment in a completely different way than was previously possible.

Technical Specifications

Encapsulation: Polyurethane

Length: 110 mm excluding mounting elements 10 mm

Diameter: 42 mm

Ground Spike Length: 75 mm (anti-corrosive material)

Existing Bandwidth: 6 Hz – 300 Hz (bandwidth can be customized according to customer specification)

Two-wire cable connection to measurement equipment.

Output Signal: Analog, (Note: the sensor can generate high output voltage under strong excitation)

Electronics: According to customer specification: (can be manufactured with built-in interface for signal amplification and digital output, wireless implementation, etc.)

IP: According to customer requirements

RMSensor One – Technical Comments from the Inventor

Over the years, significant further development of RMSensor has taken place to optimize sensitivity to the maximum. This has resulted in significantly increased sensitivity/signal response upon excitation. The magnets have received different dimensions and new surface treatment, which together provide extremely low friction, both static and dynamic. Additionally, the material in the cylinder itself has been replaced with a material with a considerably lower friction coefficient. These measures have further increased the sensor’s already high sensitivity and dynamics.

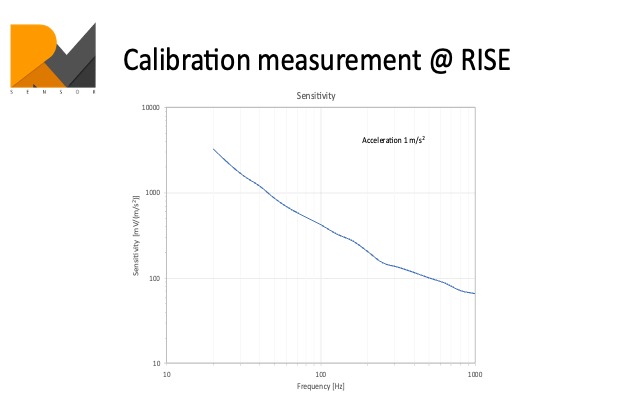

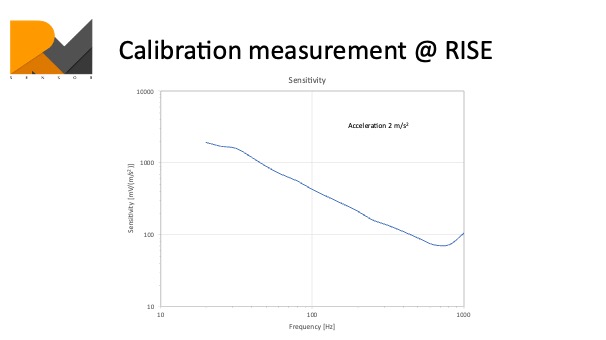

RISE is Sweden’s research institute and tests/quality assures for Sweden’s industry and institutions.